| 沥青混合料蠕变损伤模型与损伤演化 |

| |

| 引用本文: | 张启鹏, 顾兴宇, 丁济同, 胡栋梁. 沥青混合料蠕变损伤模型与损伤演化[J]. 交通运输工程学报, 2021, 21(5): 104-113. doi: 10.19818/j.cnki.1671-1637.2021.05.009 |

| |

| 作者姓名: | 张启鹏 顾兴宇 丁济同 胡栋梁 |

| |

| 作者单位: | 东南大学 交通学院,江苏 南京 211189 |

| |

| 基金项目: | 国家重点研发计划项目2017YFF0205600国家自然科学基金项目51878162 |

| |

| 摘 要: |

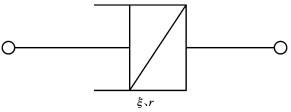

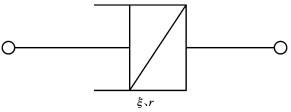

为定量描述沥青混合料的蠕变特性,考虑沥青混合料在整个蠕变过程中同时存在蠕变硬化机制和蠕变损伤劣化机制,基于分数阶微积分理论,发展了一种相对简单的分数阶蠕变损伤模型,用分数阶Maxwell模型来描述蠕变硬化机制,用损伤应变来表示蠕变损伤劣化机制,并从统计学角度推导出沥青混合料的损伤演化方程;对AC-13沥青混合料进行了不同应力水平(0.179、0.358、0.448、0.537和0.716 MPa)下的单轴压缩蠕变试验,通过Levenberg-Marquardt优化算法进行了非线性拟合,确定了不同应力水平下分数阶蠕变损伤模型的参数与损伤演化曲线;为构建不同应力水平下统一的损伤演化模型,提出了一种统计量化沥青混合料损伤演化的方法,建立了蠕变损伤与损伤应变之间的演化关系。

研究结果表明:在不同应力水平下,提出的分数阶蠕变损伤模型与试验结果的判定系数均不小于0.995,适用于描述包括衰减蠕变阶段、稳定蠕变阶段和加速蠕变阶段的整个蠕变过程;在衰减蠕变阶段,不同应力水平下沥青混合料的损伤都小于1.0×10-3,相对于蠕变破坏时的损伤0.8可以忽略不计,而进入稳定蠕变阶段以后,损伤逐渐增大;当沥青混合料的蠕变应力超过一定值时会发生蠕变破坏,其流值时间取决于所施加的应力水平;用二参数Weibull分布函数拟合所得的蠕变损伤与损伤应变之间演化关系的判定系数为0.992,说明可以建立不同应力水平下的统一损伤演化模型,且其参数只与材料性能和温度有关,与施加应力大小无关。

|

| 关 键 词: | 路面工程 沥青混合料 分数阶微积分 蠕变模型 损伤演化 损伤应变 Weibull分布 |

| 收稿时间: | 2021-04-20 |

| 本文献已被 万方数据 等数据库收录! |

| 点击此处可从《交通运输工程学报》浏览原始摘要信息 |

|

点击此处可从《交通运输工程学报》下载免费的PDF全文 |

|