| 城市轨道车轮结构振动-声辐射一体化优化方法 |

| |

| 引用本文: | 文永蓬, 刘跃杰, 周月, 圣小珍. 城市轨道车轮结构振动-声辐射一体化优化方法[J]. 交通运输工程学报, 2023, 23(3): 137-147. doi: 10.19818/j.cnki.1671-1637.2023.03.010 |

| |

| 作者姓名: | 文永蓬 刘跃杰 周月 圣小珍 |

| |

| 作者单位: | 1.上海工程技术大学 城市轨道交通学院,上海 201620;;2.西南交通大学 轨道交通运载系统全国重点实验室,四川 成都 610031;;3.上海工程技术大学 上海市轨道交通振动与噪声控制技术工程研究中心,上海 201620 |

| |

| 基金项目: | 国家自然科学基金项目(52272352);;上海市自然科学基金项目(15ZR1419200)~~; |

| |

| 摘 要: |

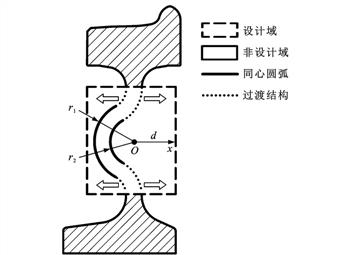

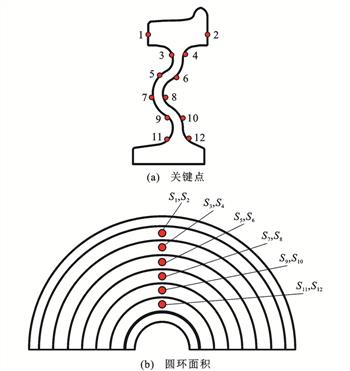

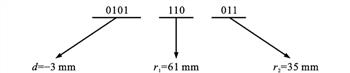

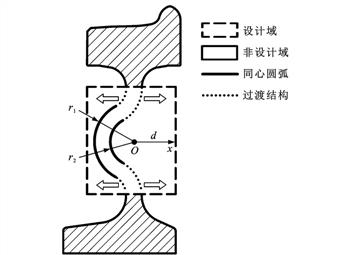

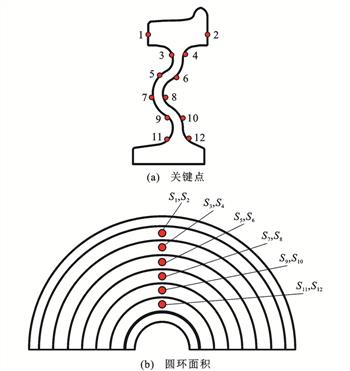

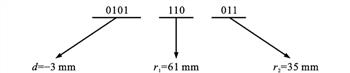

为了降低城市轨道车辆的车轮结构噪声,以服役的双S型辐板车轮为研究对象,建立了考虑振动与声辐射融合的城市轨道车轮结构噪声优化模型,获得了一种自上而下呈不等厚特征辐板的新型降噪车轮廓形,提出了以轨道车轮辐板区域为设计域的车轮结构振动-声辐射一体化优化方法;将整个辐板区域确定为设计域,分别设定编码规则、选择规则、交叉规则和变异规则,使振动-声辐射优化目标函数逐渐收敛,从而进化为较优的降噪车轮廓形,实现轨道车轮振动-声辐射结构优化设计;利用成熟有限元工具获得优化车轮的静强度、疲劳强度和振动声辐射性能,进一步验证双S型辐板车轮新型结构噪声优化结果的有效性和可靠性。

研究结果表明:车轮结构振动-声辐射一体化优化方法适用于降噪车轮的结构廓形优化,优化后车轮峰值声功率级较原双S型辐板车轮降低了4.26 dB(A),在0~5 000 Hz频段范围内声功率级峰值处降噪效果明显;从辐板结构特征上看,双S型辐板车轮的辐板由优化前的基本等厚辐板进化为不等厚辐板,车轮辐板的不等厚特征有利于降低车轮的声辐射水平,从车轮的经济和降噪性能兼顾的角度,建议采用不等厚辐板车轮廓形作为轨道车轮降噪模型。

|

| 关 键 词: | 城市轨道车辆 车轮 噪声 结构优化 声辐射 车轮廓形 |

| 收稿时间: | 2023-01-06 |

|

| 点击此处可从《交通运输工程学报》浏览原始摘要信息 |

|

点击此处可从《交通运输工程学报》下载全文 |

|