| 基于时间延迟模型的多目标优化检查决策方法 |

| |

| 引用本文: | 陆晓华, 左洪福, 白芳. 基于时间延迟模型的多目标优化检查决策方法[J]. 交通运输工程学报, 2016, 16(6): 63-71. |

| |

| 作者姓名: | 陆晓华 左洪福 白芳 |

| |

| 作者单位: | 1.南京航空航天大学 民航学院, 江苏 南京 211106;;2.中国电子科技集团公司第二十八研究所, 江苏 南京 210007 |

| |

| 基金项目: | 国家自然科学基金项目61179058 |

| |

| 摘 要: |

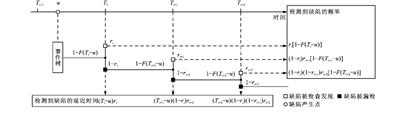

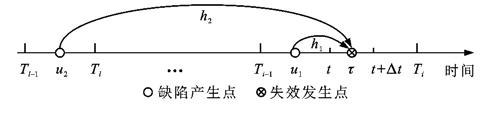

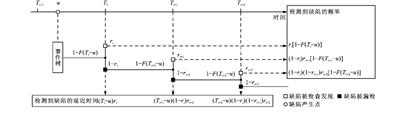

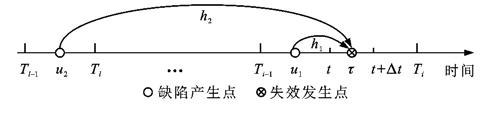

根据某航空公司货运机队的某型发动机HPTACC系统在某一周期内的预防性检查计划、检查发现的缺陷以及失效维修记录, 分析了系统在运行过程中将缺陷延迟发现时间作为安全性优化目标、将检修费用作为经济性优化目标的可行性。在预防性检查时刻发现缺陷的检修策略下, 推导了在各检查时刻基于时间延迟模型的缺陷数期望值和缺陷延迟发现时间期望值概率计算式。在缺陷退化为失效被及时发现并进行更换维修的检修策略下, 推导了在各检查间隔期内基于时间延迟模型的失效发生次数期望值概率计算式。基于2种检修策略下的概率公式, 建立了系统在给定寿命周期内的似然函数, 建立了检修费用和缺陷延迟发现时间的期望值双优化目标函数式, 运用了改进的非支配排序遗传算法优化得到双目标函数的Pareto最优解集。

根据决策者的目标偏好及其分界值对应的检修费用及缺陷延迟发现时间的经验估计值, 分别确定了系统在寿命周期内的检修费用和缺陷延迟发现时间的目标偏好函数, 通过目标偏好函数划分区间确定Pareto最优解集中各最优解的偏好区间。基于收集的检修信息和提出的方法, 对决策者将缺陷延迟发现时间期望值目标偏好定为一般、将检修费用期望值目标偏好定为很好的偏好要求进行实例分析。分析结果表明: 最优检查间隔决策约为67、70或77次起降循环, 这些检查间隔为决策者进行多目标相对最优的精确决策提供细化和更精简的选择参考。

|

| 关 键 词: | 民航发动机 时间延迟模型 Pareto最优解 多目标优化 检查决策 |

| 收稿时间: | 2016-07-13 |

|

| 点击此处可从《交通运输工程学报》浏览原始摘要信息 |

|

点击此处可从《交通运输工程学报》下载免费的PDF全文 |

|