| 铁路钢轨裂纹萌生的键型近场动力学预测模型 |

| |

| 引用本文: | 马晓川, 刘林芽, 冯青松, 徐井芒, 徐金辉, 王平. 铁路钢轨裂纹萌生的键型近场动力学预测模型[J]. 交通运输工程学报, 2021, 21(3): 228-237. doi: 10.19818/j.cnki.1671-1637.2021.03.015 |

| |

| 作者姓名: | 马晓川 刘林芽 冯青松 徐井芒 徐金辉 王平 |

| |

| 作者单位: | 1.华东交通大学 铁路环境振动与噪声教育部工程研究中心,江西 南昌 330013;;2.西南交通大学 高速铁路线路工程教育部重点实验室,四川 成都 610031 |

| |

| 基金项目: | 国家重点研发计划项目2021YFE0105600国家自然科学基金项目U1734207国家自然科学基金项目51978263江西省自然科学基金项目20192BAB216035江西省教育厅科学技术研究项目GJJ200640 |

| |

| 摘 要: |

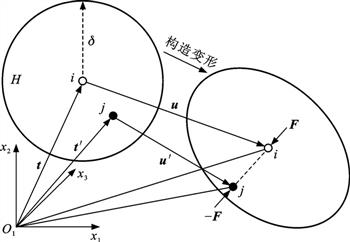

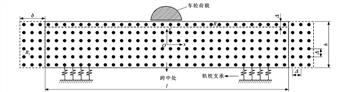

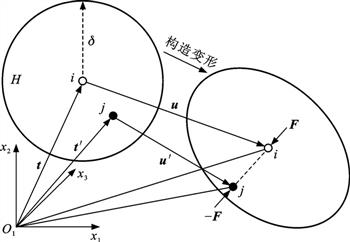

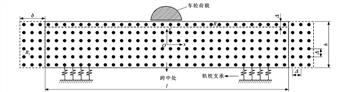

为克服经典连续介质力学在解决不连续问题时的困难,采用近场动力学方法预测铁路钢轨的裂纹萌生,以避免数学构架在不连续处的失效问题;建立了考虑轨枕支承作用的钢轨形变分析模型,分析了模型参数合理取值及收敛性,计算了车轮滚动接触荷载下的钢轨位移;根据近场动力学损伤理论,以键伸长率为指标,分别研究了车轮全滑动、粘着-滑动及无摩擦状态对铁路钢轨裂纹萌生的影响规律。

计算结果表明:近场动力学模型和经典连续介质力学模型的钢轨形变计算结果十分吻合,最大计算误差均在8%以内,验证了所建近场动力学模型的正确性;当裂纹萌生于钢轨轨头时,其启裂位置不在钢轨表面,而在钢轨表面以下约2 mm的位置,与现场观察结果一致,验证了近场动力学方法在模拟铁路钢轨疲劳裂纹萌生时的适用性;当车轮荷载位于钢轨跨中时,在车轮状态由全滑动向无摩擦转变的过程中,钢轨疲劳裂纹的萌生起点位置由轨头转移到轨底、由接触斑前端转移到接触斑中心,裂纹类型由局部滚动接触疲劳裂纹转变为整体结构疲劳裂纹,键最大伸长率由1.1×10-3降低到8.1×10-4,因此,增大切向接触应力会降低钢轨裂纹萌生寿命;当车轮荷载位于轨枕上方时,随车轮滚动状态的改变,钢轨裂纹的萌生位置始终位于轨头。

|

| 关 键 词: | 铁道工程 钢轨 疲劳裂纹 预测模型 近场动力学 数值模拟 形变分析 |

| 收稿时间: | 2020-12-18 |

| 本文献已被 CNKI 万方数据 等数据库收录! |

| 点击此处可从《交通运输工程学报》浏览原始摘要信息 |

|

点击此处可从《交通运输工程学报》下载免费的PDF全文 |

|