| 基于混合遗传算法的径向滑动轴承表面织构优化 |

| |

| 引用本文: | 张永芳, 刘成, 李莎, 李贤伟, 严冬, 吕延军. 基于混合遗传算法的径向滑动轴承表面织构优化[J]. 交通运输工程学报, 2017, 17(3): 90-98. |

| |

| 作者姓名: | 张永芳 刘成 李莎 李贤伟 严冬 吕延军 |

| |

| 作者单位: | 1.西安理工大学 印刷包装与数字媒体学院, 陕西 西安 710048;;2.重庆大学 机械传动国家重点实验室, 重庆 400044;;3.西安理工大学 机械与精密仪器工程学院, 陕西 西安 710048 |

| |

| 基金项目: | 国家自然科学基金项目51375380 机械传动国家重点实验室开放课题SKLMT-KFKT-201510 陕西省教育厅科学研究计划项目15JS068 |

| |

| 摘 要: |

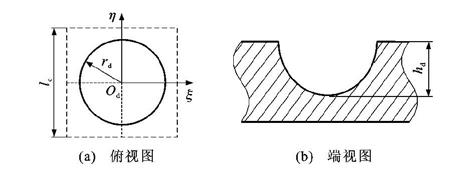

在内燃机曲轴系统的径向滑动轴承表面设计了球形凹坑织构, 以改善润滑性能; 为了获得最大的轴承承载力和最小的摩擦因数, 提出了基于序列二次规划算法和遗传算法的混合进化优化方法, 构建了径向滑动轴承球形凹坑织构的优化模型, 对凹坑织构的分布位置和结构参数进行了全局寻优, 得到了给定工况下最优的织构角度和最大深度; 为了求解径向滑动轴承的承载力和摩擦因数, 考虑曲轴和轴承表面粗糙度对油膜流动的影响, 采用质量守恒的JFO空穴算法处理油膜的破裂和再形成行为, 基于平均Reynolds方程和Greenwood-Tripp微凸体接触方程构建了球形凹坑织构径向滑动轴承的混合润滑模型, 分析了球形凹坑织构的分布位置和结构参数(数量、面积率和最大深度) 对径向滑动轴承承载力和摩擦因数的影响。分析结果表明: 径向滑动轴承的承载力和摩擦因数是凹坑面积率的单调函数; 存在最优的凹坑织构角度和最大深度使得径向滑动轴承的承载力最大与摩擦因数最小; 当偏心率由0.3增加到0.7时, 轴承承载力的提升量由13.38%下降到0.62%, 摩擦因数的降低量由0.73%逐渐下降至负数, 因此, 当偏心率较小时, 球形凹坑织构能够有效降低径向滑动轴承的摩擦因数, 增大承载力, 当偏心率较大时, 球形凹坑织构无益于轴承摩擦因数的降低。

|

| 关 键 词: | 内燃机 径向滑动轴承 表面织构 数值模拟 曲轴轴承 质量守恒边界条件 遗传优化 |

| 收稿时间: | 2017-03-25 |

| 本文献已被 CNKI 等数据库收录! |

| 点击此处可从《交通运输工程学报》浏览原始摘要信息 |

|

点击此处可从《交通运输工程学报》下载全文 |

|